'Model T moment': Ford EV announcement unveils U.S.-built, affordable electric truck

Share

Quick takeaways from the Ford EV announcement

- First vehicle on Ford’s new Universal Electric Vehicle platform: a midsize pickup built in Louisville, arriving to customers in 2027.

- Investment: $2 billion to modernize Louisville Assembly Plant; $3 billion for a Blue Oval battery park in Michigan — $5 billion and roughly 4,000 American jobs combined.

- Ambition: Deliver an affordable, high-value EV starting at $30,000 that is built in the U.S. by U.S. workers.

- Manufacturing and design innovations: prismatic LFP cells made in the U.S., a “tree” assembly layout, large unicasting body structures, and a zonal electrical architecture that removes massive wiring length.

Why this Ford EV announcement matters

Farley says that this is a "Model T moment" for Ford because the scale of change is that significant. After 122 years of vehicle building, we've found a path to re-architect how cars are designed and assembled he continued. The goal of the Ford EV announcement is simple: build an affordable EV that delights customers on design, interior space, driving pleasure and total cost of ownership — and do it profitably in the United States.

Built in America, not imported

Ford competitors often rely on overseas production for low-cost EVs. Ford chose a different path. The Ford EV announcement included a commitment to produce prismatic LFP battery cells in the U.S. and invest $2 billion in Louisville to modernize the plant — securing about 2,200 hourly jobs. Combined with Ford's Michigan Blue Oval battery park, this is a roughly $5 billion bet on American manufacturing and communities.

What the vehicle will offer

The product Ford described in the Ford EV announcement is designed to be remarkably flexible and capable:

- Spacious interior — more passenger room than a segment bestseller like the RAV4, while also providing a front trunk (frunk) and a full pickup bed.

- Performance — quicker than a Mustang twin-turbo thanks to instant EV torque and an optimized chassis.

- Connectivity and software — a new digital experience built on a zonal electrical architecture with features like Blue Cruise and more to come.

- Practical power — outlets and high-power capability to operate tools, appliances, and even supply your home. In our talk we highlighted the ability to power a house for up to six days in some scenarios.

- Affordability — starting price targeted at $30,000 to bring real ownership accessibility to millions of Americans.

How they redesigned the vehicle and the factory

The Ford EV announcement wasn’t just about a new product — it was a reveal of a new way of making vehicles. Ford commissioned a small, high-autonomy team in California to rethink every constraint. Their mandate was simple: eliminate unnecessary complexity and prioritize total system cost and manufacturability.

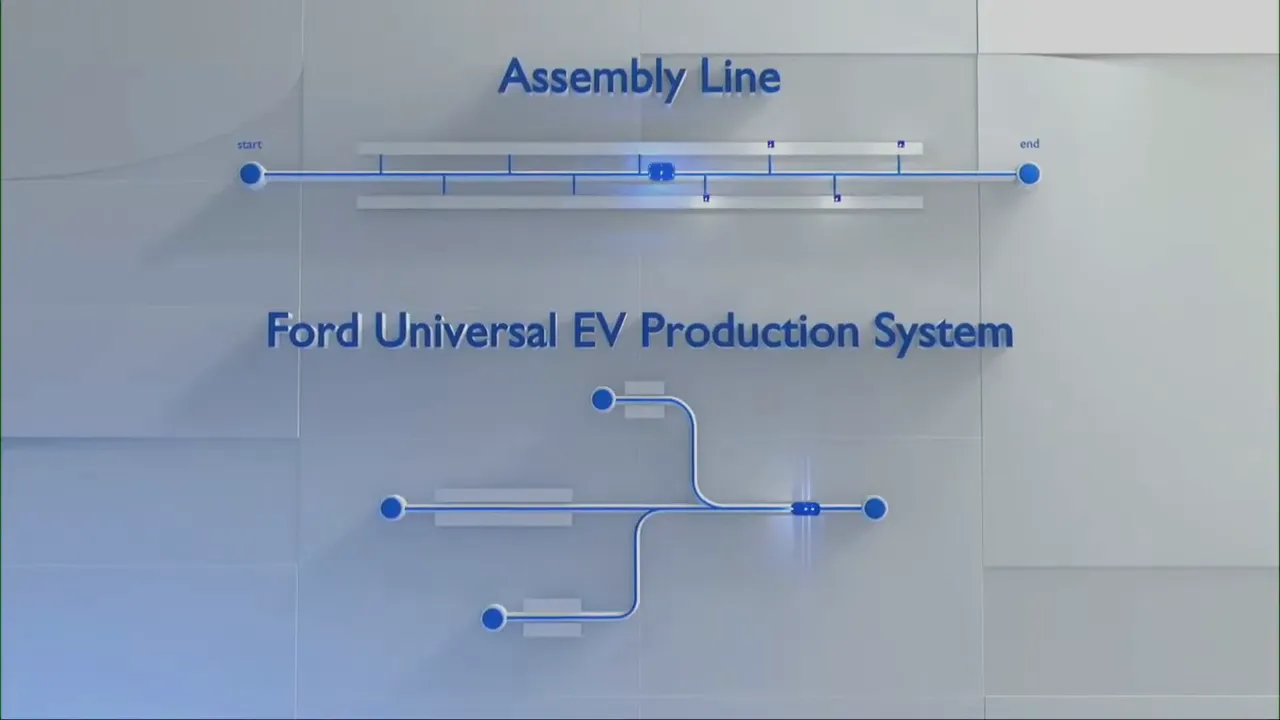

Tree production system and unicasting

Instead of a single straight moving assembly line, the Ford Universal EV production system breaks the vehicle into modular subassemblies produced in parallel and joined together in a “tree” formation. That architecture gives operators full access, drastically reduces awkward reaches, and shrinks overall build time.

Ford reportedly also pushed heavy body consolidation through large unicasts — single large castings that replace dozens or hundreds of smaller parts. The result: a vehicle with roughly one quarter of the body parts of a traditional pickup, two-thirds fewer welds, and half the fasteners.

Zonal architecture and wiring reduction

One of the biggest cost drivers for EVs is the battery. Ford engineered the vehicle so it needs markedly less battery energy to deliver the same range — in many cases the same range with roughly one-third less battery capacity compared to a typical Gen 1 EV. That smaller battery ripples savings throughout the design.

On the electrical side, Ford's ground-up zonal approach cuts wiring in dramatic fashion. Ford has removed about 4,000 feet of wiring — more than three-quarters of a mile — eliminating nearly 22 pounds from the harness. Fewer wires mean fewer failure points, simpler assembly, better ergonomics and cost savings that help make an affordable, sustainable product possible.

Workforce, safety and community impact

The Ford EV announcement emphasized respect for the workforce. Louisville Assembly Plant employees helped inform ergonomic changes: 84% fewer 24-inch reaches over the front fender, 63% reduced ingress, and a platform that reduces twisting, bending and heavy lifts. Those changes improve safety, quality and retention according to Ford.

The project pairs heavy automation with more operator-friendly workstations, extensive training (including virtual reality), and a digital infrastructure in Louisville that will be Ford's fastest globally. The result: a plant expected to be 15–20% faster on net production and capable of higher quality with fewer parts and simplified assembly.

Risks, realism and the road ahead

Farley was candid: this is a bet. No guarantees — but a deliberate, disciplined attempt to break the cycle of well-intentioned, unprofitable, affordable vehicles that faded from American plants in the past. This Ford EV announcement commits to delivering a profitable product that sustains jobs and communities, not a loss-leading compliance vehicle.

Success will require the work of engineers, manufacturing experts, union partners, suppliers and communities. As Ford execs said onstage, innovation is easy; delivering at scale is the hard part. Ford says its team has the mandate, the tools, and the resolve to try.

Bottom line

The Ford EV announcement marks a clear strategic direction for Ford: design radically to cut cost and complexity, manufacture differently to improve ergonomics and throughput, and build an affordable, high-value EV in the United States. If it succeeds, it will be a generational shift in how American cars are made — and who gets to build and buy them.

Key facts reminder: midsize pickup on the Universal Electric Vehicle platform arriving 2027, Louisville investment $2 billion, Blue Oval battery park $3 billion, starting price targeted at $30,000, and deep manufacturing innovations tied to reduced parts counts, wiring, and battery size.

Ford says it is just getting started

As we move from announcement to execution, the work begins. From Kentucky to the world, we intend to build a vehicle that proves affordable electric mobility can be made in America — by American workers — and be profitable for Ford. Now the hard but exciting work of delivering on it begins. That was the promise of this Ford EV announcement.

What do you think about Ford's EV Announcement and the upcoming mid-size EV Truck? Share your thoughts and experiences!

If this helped you, please considering buying me a coffee. Did I get something wrong? Let me know in the comments section or visit our Link Tree to contact us

This article was created based on information from the following video 'Model T moment': Ford unveils plans to design and build electric vehicles in USA